Processing Industry

ONE OF THE MOST EXTENSIVE and at the same time varied area that uses Sauer compressors is the processing industry. With the help of Sauer’s medium and high pressure compressors, materials and other substances can be converted, shaped, blended, cast or pressed. Equipped with reliable and economical compressors as well as its knowledge and understanding of the overall processes involved, Sauer is the ideal partner when it comes to finding solutions for individual applications.

ELGI Sauer customers benefit from the following advantages

- The very latest compressors, control systems, compressed-air treatment systems and accessories

- Optimum customer services beginning with the initial enquiry and extending over the entire product life

- 100% compressor check at final pressure inclusive of 3.1 inspection certificate

- Long operating life with guaranteed availability of replacement parts (minimum 25 years)

- Compressors designed for permanent operation (S1 – 24 /7)

- Minimal downtimes, ensuring high product availability

- MTBF , MTBO , MTTR

- Optimum service concepts

Metal treatment

The fact that modern manufacturing procedures speed up processes and are therefore more efficient and less expensive signifies that they offer an important competitive advantage. In the field of metal treatment, it is Sauer compressors which allow you to benefit from this advantage. Working together with our customers, we develop innovative and integrated system solutions, i. e. systems which allow you not only to supply a process with gases but also to remove them again and store them for use in the next step. Users also benefit from the particularly low leakage rates of our gas compressors and from our turn-key installations, some of which have a flexible design.Who are ELGI Sauer Compressors’ customers?

- Automotive suppliers

- Aviation suppliers

- Manufacturers of hardening furnaces

What are ELGI Sauer Compressors used for?

- Hardening materials

Which ELGI Sauer product ranges are used?

Checking and testing

All products which are to be used under a certain pressure must undergo initial testing at a pressure which is many times greater than that required. If necessary, their gas tightness must also be checked, when using highly volatile gases. Although water was previously used to carryout pressure checks, an improved procedure involving air or nitrogen is now used instead. During leakage checks, Sauer compressors help to recycle the gas which escapes, e. g. helium, and then return it to the process. The advantages are evidently seen. Individual process steps, namely, cleaning and drying during water checks, are shortened or can be dispensed with entirely. In addition to this, the loss of expensive gases can be avoided.What are ELGI Sauer Compressors used for?

- Checking brakes and other components under pressure

- Checking airbags and other components under pressure

- Checking injection systems under pressure

- Checking the gas tightness of components using helium

- Checking valves and other fittings under pressure

- Checking containers under pressure

Who are ELGI Sauer Compressors’ customers?

- Automotive manufacturers

- Automotive suppliers

- Manufacturers of valves and other fittings

- Manufacturers of pressurised containers

Which ELGI Sauer product ranges are used?

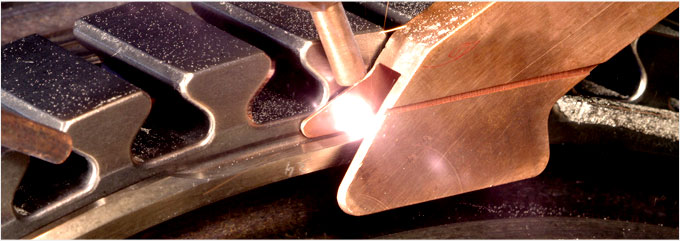

Laser metal cutting

The cutting of metals with the help of a laser has replaced traditional mechanical methods and offers clear advantages. For example: the processes involved are shortened and the cut surfaces are not contaminated by the material of the cutting dies. However, the laser environment must be free from ambient air, if an optimum cut is to be achieved. To ensure that this is the case, nitrogen is used. This nitrogen is preferably produced on site, using the pressure swing adsorption (PSA) process or membranes. This helps to ensure that companies are not reliant on gas suppliers. After the PSA process has been carried out, Sauer compressors are used to boost the nitrogen to a pressure of 40 or 300 bar. The higher pressure of 300 bar offers particular advantages as it enables large amounts of gas which are normally sufficient for a number of days, to be stored quickly. Not only do users benefit from greater operational reliability, they do not need to operate their high-pressure compressor for such long periods and can therefore take advantage of the times, where cheaper energy tariffs apply. Added to this, less extra equipment is required upstream, when a pressure of 300 bar is used.Who are ELGI Sauer Compressors’ customers?

- Metal treatment companies

- Manufacturers of machine tools for laser cutting

- Manufacturers of nitrogen generators/nitrogen membranes

What are ELGI Sauer Compressors used for?

- Creating an inert atmosphere surrounding the laser

Which ELGI Sauer product ranges are used?

Nitrogen – Boosting and storage

Nitrogen plays an essential role in many other applications as well. Sauer compressors are popular choices, when it comes to storing large amounts of the gas so that it is available quickly and in sufficient quantities, while carrying out the desired processes. There is a good reason for this. Each Sauer gas compressor is engineered to offer the high level of flexibility required, to satisfy an extremely wide range of requirements such as different suction pressures, final pressures or gas quality. As a result, they are frequently used in a variety of medium and high-pressure applications.Who are ELGI Sauer Compressors’ customers?

- Chemical manufacturers

- Tyre manufacturers

- Manufacturers of fire-extinguishing systems

- Manufacturers of nitrogen generators/membranes

What are ELGI Sauer Compressors used for?

- Creating an inert atmosphere

- Transporting media

- Inflating aircraft tyres

- Filling fire-extinguishing systems

Which ELGI Sauer product ranges are used?

Manufacturing composite materials

The manufacture of composite materials is also part of the processing industry. In both the wooden materials and plastics industry, different materials are pressed together, under the influence of pressure and heat, in order to produce materials with special characteristic properties. In the field of plastics, so-called autoclaves (special pressurised containers which can be sealed to make them gas tight) are used. Sauer compressors offer an efficient way of ensuring that the necessary pressure is available for these processes.Who are ELGI Sauer Compressors’ customers?

- Producers of wood-fibre composite materials

- Producers of plastic composite systems

- Manufacturers of autoclaves

What are ELGI Sauer Compressors used for?

- Filling and generating pressure for autoclaves

- Raising pressure for wood presses